Polypropylene Lofted Pleated Filter Cartridges

Ecologix Polypropylene Lofted Pleated Filter Cartridges (GHLS Series) provide a 100% polypropylene element designed for the removal of agglomerated and deformable contaminants in oils and gels.

With its added loft, the GHLS is an ideal combination of both depth and pleated depth functionality. This allows for high retention and holding capacity without inhibiting throughput. The pleated depth media is encapsulated in an integral, continuous length, thermally-bonded structure for cleanliness, pressure tolerance, and chemical inertness. Offered in both absolute rated (up to 99.98% retention) and nominally rated (90% retention) grades in common adapter configurations. Manufactured in a clean room environment to maintain high standards of purity and cleanliness.

Filtration Applications

- Agglomerated Particles

- CBD Oils

- CMP Slurries

- Coatings

- Edible Oils

- Gels

- Inks

- Paints

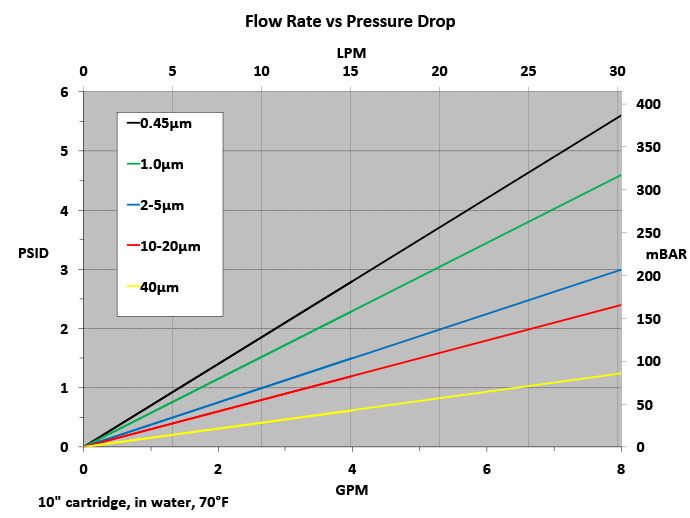

Flow Rate vs Pressure Drop

Construction Materials

- Filtration Media: Polypropylene

- Support Media: Polypropylene & PE/PET

- End Caps: Polypropylene

- Center Core: Polypropylene

- Outer Support Cage: Polypropylene

- O-Rings/Gaskets: Buna, EPDM, Silicone, Teflon® Encapsulated Viton®, Viton®, Teflon® Encapsulated Silicone

Dimension (Nominal)

| Length | 10 to 40 in (25.4 to 101.6 cm) nominal |

|---|---|

| Outside Diameter | 2.70 in (7.0 cm) |

Operating Conditions

| Change Out ∆P (recommended) | 35 PSID (2.4 bar) |

|---|---|

| Temperature (max) | 176˚F (80˚C) |

| Differential Pressure (max) | 60 PSID (4.1 bar) at 68˚F (20˚C) |

Sanitization/Sterilization

| Filtered Hot Water | 176˚F (80˚C) for 30 min |

|---|---|

| Steam Sterilization | 250˚F (121˚C) for 30 min multiple cycles |

Chemicals: Cartridges are compatible with most chemical sanitizing agents.

Note: Stainless steel insert option required for all cartridges being hot water sanitized

or steam sterilized.

Food Safety Compliance

Materials of construction comply with FDA regulations for food and beverage contact use as detailed in the US Code of Federal Regulations, 21CFR. Materials used to produce filter media and hardware are deemed safe for use in contact with foodstuffs in accordance with EU Directives 1935/2004, and/or 10/2011.

Toxicity

All polypropylene components meet the specifications for biological safety per USP Class VI - 121˚C for plastics.

Polypropylene Lofted Pleated Filter Cartridges - Ordering Details

| Rating (µ) | Retention | Length | End Cap Style | O-Rings (For B & D Flange Only) | Adders |

|---|---|---|---|---|---|

| 0.45 | A = Absolute | 10” (25.4 cm) | 2 = DOE Flat Gasket | B = Buna | CS = 316SS Compression Spring |

| 1.0 | N = Nominal | 20” (50.8 cm) | 3 = 222 w/Fin | E = EPDM | FG = Glass Reinforced PP Core |

| 2.0 | 30” (76.2 cm) | 4 = 222 w/Flat Cap | S = Silicone | HP = Heavy Poly Core | |

| 5.0 | 40” (101.6 cm) | 5 = 222 w/Spring | T = Teflon® Encapsulated Viton® | I = Stainless Steel Insert1 | |

| 10.0 | 6 = 226 w/Flat Cap | V = Viton® | R = Megaohm Rinse | ||

| 15.0 | 7 = 226 w/Fin | T= Teflon® Encapsulated Silicone | SS = Stainless Steel Core | ||

| 20.0 | 8 = 226 w/Spring | ||||

| 40.0 | 16 = 213 Internal O-Ring | ||||

| 28 = 222 3-Tabs w/ Fin |