Commercial / Industrial Bakery Wastewater Treatment

Large commercial bakeries whose products include cakes, pies, cookies, biscuits, brownies, rolls, and a variety of other breads and desserts, generate wastewater with loads of contaminants too high for municipal discharge without pretreatment. This is because many POTWs now use biological treatment that would be overwhelmed by these loads.

Background / hazards presented by Bakery Wastewater

Bakeries use large volumes of butter, flour, shortening, sugar, and fillings of various types. These produce, on average, levels of contaminants like the wastewater illustrated by the table below. It shows the high level of BOD, suspended solids and fats, oils, and grease that preclude the wastewater being processed without pretreatment.

Typical content levels of industry wastewater before treatment

| COD | BOD | TSS | TP | TKN | FOG |

|---|---|---|---|---|---|

| 7,000 | 3,200 | 6,000 | 6.8 | 36 | 820 |

Influent Characteristics

These figures represent typical measured content levels of major contaminants in wastewater as it issues from the factory:- COD (Chemical Oxygen Demand) - 7,000 mg/L

- BOD (Biological Oxygen Demand) - 3,200 mg/L

- TSS (Total Suspended Solids) - 6,000 mg/L

- TP (Total Phosphorous) - 50 mg/L

- TKN (Total Kjeldahl Nitrogen) - 100 mg/L

- FOG (Fats, Oil & Grease) - 820 mg/L

Effluent - Required Characteristics

These figures represent typical required content level limits of major contaminants in treated wastewater before it is allowed to be discharged to publicly owned treatment works (POTWs):- COD (Chemical Oxygen Demand) - 1,000 mg/L

- BOD (Biological Oxygen Demand) - 250 - 500 mg/L

- TSS (Total Suspended Solids) - 250 mg/L

- TP (Total Phosphorous) - 20 mg/L

- TKN (Total Kjeldahl Nitrogen) - 50 mg/L

- FOG (Fats, Oil & Grease) - 100 mg/L

Optimum Treatment Solutions

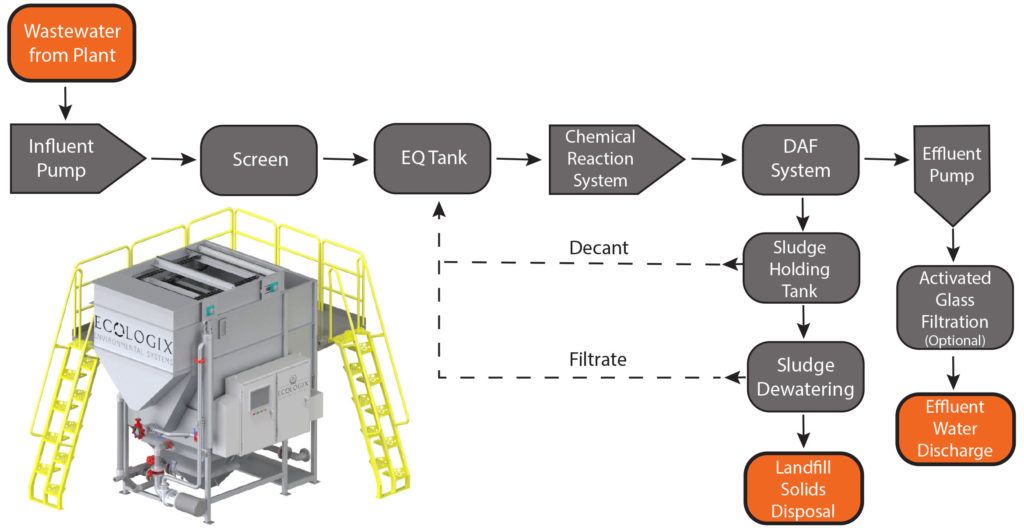

Pretreatment of wastewater from a bakery is necessary before discharging to a municipal sewer system because municipal treatment plants are incapable of removing the contaminant densities typical of commercial bakery wastewater. A very efficient and cost-effective way to accomplish effective pretreatment is through the operation of a Dissolved Air Flotation (DAF) system. These systems are the optimal solution for removal of materials such as solids (TSS), fats, oils, and grease (FOG).

Pretreatment using an enhanced DAF system in a commercial bakery will allow for reduction of FOG by up to 99% and Total Suspended Solids (TSS) by up to 97%. The requirement for flocculants, as well as pH adjustment of the water, for effective FOG removal can be fully automated, using the Ecologix Enhanced Dissolved Air Flotation System.

Process Description

- A DAF system utilizes a separation technique that injects microscopic air bubbles into the DAF tank.

- These tiny bubbles attach to the insoluble pollutant materials, floating them to the surface the way a life preserver keeps a person afloat.

- Certain materials used in the baking process are heavier than water. They require the addition of flocculants, which attract suspended contaminant particles and air. When combined, these two substances cause the pollutants to join in clusters and force them to float to the pretreatment vessel's surface.

- These accumulating contaminants at the surface of the DAF vessel are what is known as "sludge."" They are then scraped off the surface of the water and removed from the treatment process.

- Clean water then exits at the bottom of the DAF vessel and can now be safely discharged to the sewer.

Preview the impressive results are Enhanced Dissolved Air Flotation System (E-DAF) produced processing the wastewater from a US based commercial bakery.

If your commercial bakery is struggling to meet strict new wastewater discharge requirements, call 1-678-514-2100 or contact us today. We will take care of setting you up with an onsite package pretreatment plant, so you can stay compliant while getting back to what you do best.