IFAS and MBBR systems revolutionize efficiency and sustainability in tissue, pulp, and paper industries

Pulp, paper, and tissue plants face mounting pressure to comply with stringent environmental regulations, manage high-strength wastewater, and maintain cost-effective operations with aging treatment systems. Many facilities rely on outdated biological processes like conventional activated sludge (CAS), which struggle to handle the unique demands of industrial effluents. Upgrading to Moving Bed Biofilm Reactor (MBBR) or Integrated Fixed-Film Activated Sludge (IFAS) systems offers compelling advantages in performance, cost, and sustainability tailored to these industries.

Enhanced Treatment Capacity

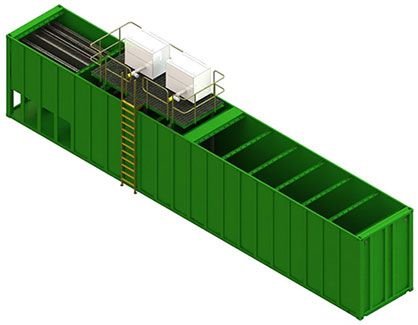

MBBR and IFAS significantly enhance treatment capacity without requiring expansive new infrastructure—a critical benefit for space-limited industrial sites. MBBR employs free-floating plastic media to cultivate a biofilm that efficiently degrades organic matter, while IFAS integrates this with suspended activated sludge for even greater efficiency. Retrofitting these systems into existing tanks can double or triple capacity, accommodating the high organic loads typical of pulp and paper wastewater without major facility expansions.

Improved Resilience and Flexibility

The variable wastewater composition from pulp, paper, and tissue production—rich in lignins, cellulose, and chemicals—can overwhelm traditional (CAS) systems and older technology. MBBR and IFAS offer superior resilience. The biofilm in MBBR thrives under fluctuating organic and hydraulic loads, ensuring stable treatment. IFAS adds flexibility by combining biofilm and suspended biomass, allowing adjustments for specific effluent challenges. This robustness ensures consistent compliance with discharge permits, even during production spikes or process changes.

Cost-Effectiveness Over Time

Retrofitting to MBBR or IFAS can be more cost-effective than constructing new treatment systems from scratch. Leveraging existing tanks cuts capital expenses, a key consideration for budget-conscious plants. These technologies also lower operating costs through optimized aeration and reduced sludge production—crucial given the high sludge volumes from pulp, paper, and tissue production processes. Decreased energy use and sludge disposal fees translate to substantial long-term savings.

Simplified Operation and Maintenance

Older CAS systems demand intensive oversight to manage sludge and maintain performance, straining plant resources. MBBR and IFAS systems streamline operations. The self-regulating biofilm in MBBR reduces sludge handling complexity, while IFAS can be retrofitted into existing plant infrastructure. Maintenance is minimal— Ecologix's Eco Chip MBBR media lasts for years, and IFAS requires little additional upkeep. This simplicity reduces labor demands and minimizes downtime, boosting operational reliability.

Sustainability Benefits

Sustainability is increasingly vital in the pulp, paper, and tissue sectors. Ecologix's MBBR and IFAS bio systems align with these goals by cutting energy use and improving pollutant removal—think BOD, COD, and nutrients—protecting waterways downstream. Their efficient designs lower carbon footprints, and enhanced treatment prepares plants for stricter future regulations, supporting both environmental stewardship and corporate responsibility.

Conclusion

For pulp, paper, and tissue plants, converting outdated biological treatment systems to MBBR or IFAS is a strategic upgrade. These technologies deliver higher capacity, resilience, and cost savings while simplifying operations and enhancing sustainability. For facilities aiming to modernize wastewater management without disrupting production or the bottom line, Ecologix's MBBR and IFAS designs are proven, industry-smart solutions. Reach out to Ecologix Environmental Systems today for your free quote and take the first step toward a smarter, greener wastewater future.

If your facility requires an upgrade or replacement of existing equipment, consider Ecologix www.ecologixsystems.com , as your one-stop provider for wastewater treatment systems, including, engineering design, fabrication, installation and startup. For additional information Call (678) 514-2100.