Industrial Systems for Wastewater Treatment

Ecologix provides comprehensive wastewater treatment technologies and services for the all areas of industry including automotive, bakeries, food and beverage, slaughterhouses, mining, municipal, produced water, and more.

Bio-Clear Packaged Sewage Treatment System

The Bio-Clear packaged sewage treatment system is designed for developments like hospitals, hotels, and rural communities that are required to treat wastewater to levels suitable for discharge.

Incline Plate and Tube Clarifiers

Ecologix clarifiers are designed for minimal footprint and rapid particle settling. Our clarifiers are simple to operate and maintain, flexible in treatment capacity, and highly effective at removing solids in waste streams with pollutants that tend to sink.

Chemical Feed and Mixing Systems

Ecologix chemical feed and chemical mixing systems are engineered to meet the requirements specific to your application. Our design is highly efficient, easy to maintain, cost-effective and well suited for any chemical process, regardless of tank size, quantity, or chemical viscosity.

Dissolved Air Flotation (DAF) System

The Ecologix Enhanced DAF is a complete primary (phys/chem) treatment system. It is an incredibly versatile and efficient chemical precipitation and physical separation system. The E-DAF combines several proven technologies such as DAF (Dissolved Air Flotation) and DGF (Dissolved Gas Flotation), into a single platform.

EvapoDry Wastewater Evaporators

The EvapoDry employs a submerged, low temperature burner to evaporate solutions at approximately 180° F - 186° F, eliminating the vaporization of heavy metals and the organic breakdown of most solids. Precipitated solids are removed from the evaporator tank bottom with our unique hands off, user friendly conveyor system.

Floctubes and Chemical Reaction Tanks

Our innovative DAF system has the option to include an enhanced floctube assembly to increase contact time and improve dramatically system performance.

Integrated Bio-Reactor (IBR)

The Integrated Bio-Reactor (IBR) is a unique modification of the activated sludge process in which the clarifier is placed within the aeration tank. The above-ground design reduces system footprint and saves on costs associated with excavating and constructing traditional concrete basins.

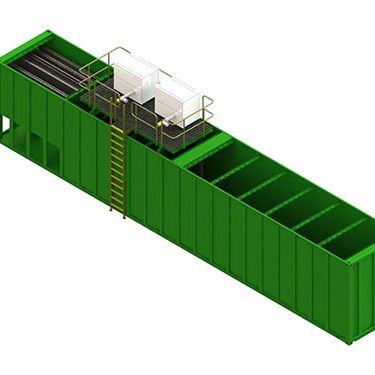

Integrated Treatment System for Frac Water Management (ITS)

The Ecologix ITS-1500 (1,500gpm or 51,400bbl/day), has the largest capacity and smallest footprint compared to any of our previous generations of Flowback and Produced Water treatment systems. The system is designed to precipitate and remove TSS (Total Suspended Solids), Emulsified Oil and Dissolved Metal (such as Iron).

Membrane Bioreactor (MBR)

The Ecologix Envirocube MBR is an ultrafiltration membrane with uniform pore size and high rejection capacity. Envirocube modules consist of flat sheet PVDF ultrafiltration membrane cassettes, air diffusers and a product water manifold.

Moving Bed Biofilm Reactor (MBBR)

The Ecologix MBBR is a highly effective biological treatment process based on a combination of conventional activated sludge process and biofilm media. The MBBR process utilizes floating High Capacity MicroOrganism BioChips media within the aeration and anoxic tanks.

Reverse Osmosis (RO) Membrane System

Reverse osmosis (RO) is the best alternative for high volume/high quality water treatment. Reverse Osmosis can remove many types of molecules and ions from solutions, including salts. It is used in both industrial processes and the production of potable water from brackish water or sea water.

Ultrafiltration (UF) Membrane System

Ultrafiltration (UF) produces a high quality effluent, devoid of nearly all TSS (Total Suspended Solids), FOG (Fat Oil and Grease) and other contaminants such as Dissolved Metals.