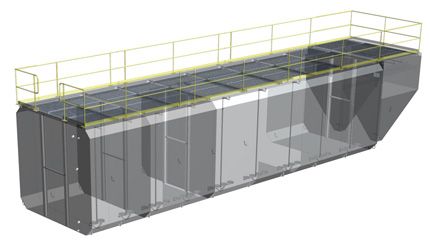

Bio-Clear Packaged Sewage Treatment System

The Bio-Clear packaged sewage treatment system is designed for developments like hospitals, hotels, and rural communities that are required to treat wastewater to levels suitable for discharge. The multi-stage treatment process includes screening, diffused aeration, clarification, sludge recirculation, sludge digestion, filtration, and disinfection. Pre-engineered modular components such as diffused air blowers, aeration tanks, sludge holding tanks, clarifiers, and disinfection units allow for the package plants to be sized specifically for the customer's application. Systems are designed to handle a range of influent flows and consistently reduce TSS and BOD.

To discuss your biological treatment solution, call on one of our professional Engineers to request a budgetary proposal for your specific requirements.

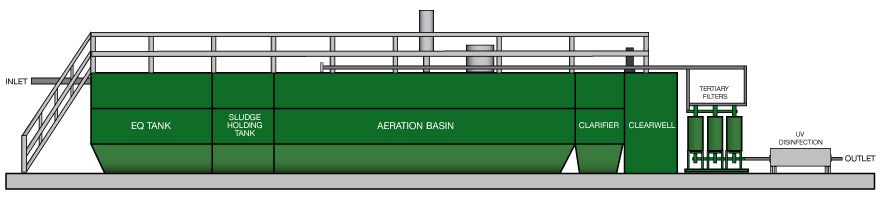

How it Works

Wastewater enters the package plant first passing through a bar screen for large solids removal. In the equalization tank water is retained to create a homogenous mixture prior to treatment. Upon entry into the aeration basin, water is mixed with an active biomass in a rolling action which takes place over the length and width of the chamber. The chambers are filleted on each side and the bottom to enhance the rolling motion and eliminate any "dead zones" in the tank. This design feature also minimizes the accumulation of scum and froth in the aeration tank.

After sufficient contact time in the aeration chamber, water flows into the clarifier and solids settle in the hopper-bottom tank. Solids are recirculated through the system or withdrawn as needed. Clean water flows through the clarifier into the clear well where it is re-pressurized and passed through the tertiary filters and disinfection systems. Learn more about a bioclear installation at a power plant in Wyoming where extreme temperatures were a concern.

View a selection of our Bio-Clear Installations

Available Bio-Clear Packaged Treatment Systems

| Model | Operating Capacity (GPD) | Dimensions | Flow EQ | Sludge Holding | Aeration Tank | Clarifier | Shipping Weight (lbs.) |

|---|---|---|---|---|---|---|---|

| BC-3-ES | 3000 | 9'6"H x 8'W x 16'L | 2'6" | 2' | 7' | 4'6" | 5900 |

| BC-5-ES | 5000 | 9'6"H x 8'W x 21'6"L | 3'6" | 2'6" | 11' | 4'6" | 7900 |

| BC-7-ES | 7000 | 10'H x 10'W x 23'3"L | 3'9" | 2'6" | 11'6" | 5'6" | 9800 |

| BC-10-ES | 10000 | 11'H x 10'W x 28'3"L | 5' | 2'6" | 14'9" | 6' | 12400 |

| BC-12-ES | 12000 | 11'H x 10'W x 33'6"L | 6' | 2'6" | 17'9" | 7'3" | 14100 |

| BC-15-ES | 15000 | 11'H x 10'W x 41'3"L | 7'3" | 3'6" | 22' | 8'6" | 16000 |

| BC-18-ES | 18000 | 11'H x 11'W x 40'L | 7'9" | 3'9" | 23'6" | 5'6" | 17900 |

| BC-20-ES | 20000 | 11'H x 12'W x 42'6"L | 8'3" | 3'9" | 24'6" | 6' | 18900 |

| BC-25-ES | 25000 | 11'H x 12'W x 51'6"L | 10' | 4'6" | 30' | 7' | 23500 |

| BC-30-ES | 30000 | 11'H x 12'W x 61'6"L | 12' | 5'6" | 36' | 8' | 27500 |

| BC-35-ES | 35000 | 11'H x 12'W x 71'6"L | 13'9" | 6'6" | 41'9" | 10' | 34400 |

| BC-50-ES | 50000 | 11'H x 12'W x 99'L | 20' | 9' | 60' | 10' | 43600 |

| BC-60-ES | 60000 | 11'H x 24'W x 65'6"L | 12' | 5'6" | 36' | 12' | 56000 |

| BC-75-ES | 75000 | 11'H x 24'W x 78'6"L | 15' | 6'6" | 45' | 12' | 71800 |

| BC-90-ES | 90000 | 11'H x 24'W x 92'L | 18' | 8' | 54' | 12' | 80800 |

| BC-100-ES | 100000 | 11'H x 24'W x 101'L | 20' | 9' | 60' | 12' | 87000 |

Design Flow Guidelines

Information on flow rate is necessary for the design of an effective wastewater treatment and disposal system. The wastewater flow rates of existing facilities can often be measured. The below table can be used as a basis for the design of sewage treatment and disposal facilities for new developments, and for existing establishments when the hydraulic loading cannot be measured. Alternatively, water-usage data can be used to estimate wastewater flow, if it is available for an establishment. Adjustments should be made for infiltration, and for water that will not reach the sewer (e.g. boiler water).

| Type of Facility | Flow Rate Per Person (gal./day) | Flow Rate Per Unit (gal./day) |

|---|---|---|

| Airports | ||

| (Per Passenger) | 3 | |

| (Per Employee) | 15 | |

| Apartments | 75 | |

| 1 Bedroom | 150 | |

| 2 Bedroom | 300 | |

| 3 Bedroom | 400 | |

| Bathhouse | ||

| (Per Swimmer) | 10 | |

| Boarding House | 75 | |

| Bowling Alley | ||

| (Per Lane - No Food) | 75 | |

| (With Food - Add Food Service Value) | ||

| Campgrounds (Recreational Vehicle - Per Site) | ||

| Sewered Sites | 100 | |

| Central Facilities | ||

| Served Sites, 300' Radius | ||

| Peripheral Sites, 500' Radius | 100 | |

| Subractions From Above | 75 | |

| No Showers | 25 | |

| Dual Service (Central Facilities and Sewered Facilities Overlapping the Central)) | 25 | |

| Campground (Summer Camp) | ||

| Central Facilities | 50 | |

| Separate Facilities | ||

| Toilet | 10 | |

| Shower | 25 | |

| Kitchen | 10 | |

| Campground Dumping Stations | ||

| (Per Unsewered Site) | 10 | |

| (Per Sewered Site) | 5 | |

| Camps, Day | 13 | |

| Add for Lunch | 3 | |

| Add for Showers | 5 | |

| Carwashes, Assuming No Recycle | ||

| Tunnel, Per Car | 80 | |

| Rollover, Per Car | 40 | |

| Handwash, Per 5 Minute Cycle | 20 | |

| Churches - Per Seat | 3 | |

| (With Catering, Add Food Service Value) | ||

| Clubs | ||

| Country | ||

| Per Resident Member | 75 | |

| Per Non-Resident Member | 25 | |

| Racquet (Per Court Per Hour) | 80 | |

| Factories | ||

| Per Person/Shift | 25 | |

| Add for Showers | 10 | |

| Food Service Operations (Per Seat) | ||

| Ordinary Restaurant | 35 | |

| 24 - Hour Restaurant | 50 | |

| Restaurant Along Freeway | 70 | |

| Tavern (Little Food Service) | 20 | |

| Curb Service (Drive-In, Per Car Space) | 50 | |

| Catering, or Banquet Facilities | 20 | |

| Hair Dresser (Per Station) | 170 | |

| Hospitals (Per Bed) | 175 | |

| Hotels (Per Room) Add for Banquet Facilities, Theatre, Night Club, as Applicable | 120 | |

| Homes | ||

| One Bedroom | 150 | |

| Two Bedroom | 300 | |

| Three Bedroom | 400 | |

| Four Bedroom | 475 | |

| Five Bedroom | 550 | |

| Institutions | ||

| (Other than Hospitals) | 125 | |

| Laundromats (Per Machine) | 580 | |

| Mobile Home Parks | ||

| Less Than Five Units: Use Flow Design for Homes | ||

| Twenty or More Units: Per Trailer | ||

| Double Wide | 200 | |

| Five to Twenty Units - Use Prorated Scale | 300 | |

| Mobile Home Parks | ||

| Per Mobile Home Space (without service building) | 150 | |

| Per Mobile Home Space (with service building) | 175 | |

| Motels | ||

| Per Living Unit | 100 | |

| With Kitchen | 150 | |

| Office Buildings | ||

| Per Employee | 15 | |

| Per Square Foot | 0.1 | |

| Dentist - Per Chair/Day | 750 | |

| Parks (Per Picnicker) | ||

| Restroom Only | 5 | |

| Showers and Restroom | 10 | |

| Schools (Per Student) | ||

| Boarding | 75 | |

| Day | 10 | |

| Cafeteria - Add | 5 | |

| Showers - Add | 5 | |

| Service Station | ||

| Per Toilet (Not Including Car Wash) | 400 | |

| Swimming Pools (Per Swimmer) | 10 | |

| Sports Stadium | 5 | |

| Theatre | ||

| Drive-In (Per Space) | ||

| Movie (Per Seat) | ||

| Dinner Theatre, Individual (Per Seat) | 20 | |

| With Hotel | 10 | |