Integrated Bio-Reactor Biological Sewage Treatment System (IBR)

The Integrated Bio-Reactor (IBR) is a unique modification of the activated sludge process in which the clarifier is placed within the aeration tank. The above-ground design reduces system footprint and saves on costs associated with excavating and constructing traditional concrete basins.

Composed of aerobic, anoxic, and clarification zones, the IBR is designed to treat typical municipal wastewater. The operation and maintenance of the IBR is simple, as the system's only moving mechanical parts are the aeration blowers, which drive air into the reactor.

To discuss your wastewater treatment solution, call on one of our professional Engineers to request a budgetary proposal for your specific requirements.

IBR Exclusive Features

- Bolted-steel structure eliminates need for expensive concrete tanks

- 30-foot high tank walls allow for increased oxygen transfer

- Internal clarifier tank reduces system footprint

- Reduced detention time delivers higher processing rate

- Minimal moving parts means lower power requirement and reduced maintenance

- High efficiency aeration system

How the IBR Works

The Integrated Biological Reactor® has a vertical installation that results in a comparatively small footprint. The vertical installation also allows for an increase in the oxygen transfer rate to the wastewater. The wastewater is aerated using atmospheric air; this air is aspirated to the liquid by passing it through an air blower and a series of diffusers. This results in a simple and effective aerobic process.

The air is discharged through the bottom of the bioreactor. At this point the air is released flowing upward from roughly twice the standard depth of a normal Activated Sludge system. This, in turn, results in greater efficiency of Oxygen saturation into the wastewater.

The result of this retention time of air in the effluent, together with the perfect mixing of the extremely small micro bubbles of air with the liquid, creates the most effective and highest diffusion coefficient of oxygen in the water to date.

View some installation photos of the IBR

Integrated Bio-Reactor System Models

| Model | Flow (GPD) | m3/day | Population Equivalent | Outer Tank Diameter (ft) | Power Installed (kW/hr) |

|---|---|---|---|---|---|

| IBR-100 | 100,000 | 378.5 | 1893 | 18 | 9 |

| IBR-200 | 200,000 | 757 | 3785 | 25 | 18 |

| IBR-300 | 300,000 | 1135.5 | 5678 | 31 | 26 |

| IBR-400 | 400,000 | 1514 | 7570 | 36 | 35 |

| IBR-500 | 500,000 | 1892.5 | 9463 | 40 | 44 |

| IBR-600 | 600,000 | 2271 | 11355 | 44 | 53 |

| IBR-700 | 700,000 | 2649.5 | 13248 | 48 | 62 |

| IBR-800 | 800,000 | 3028 | 15140 | 51 | 70 |

| IBR-900 | 900,000 | 3406.5 | 17033 | 54 | 79 |

| IBR-1000 | 1,000,000 | 3785 | 18925 | 57 | 88 |

IBR Competitive Performance Analysis

| Process | Solids Retention Time (day) | F/M (kg BOD/kg MLVSS day) | Volumetric Load (kg BOD/m3/day) | MLSS (mg/L) | Total Hydraulic Retention Time (hr) | Return Activated Sludge (% influent) |

|---|---|---|---|---|---|---|

| High Rate Aeration | 0.5 - 2.0 | 1.5 - 2.0 | 1.2 - 2.4 | 200 - 1000 | 1.5 - 3 | 100 - 150 |

| SBR - Sequencing Batch Reactor | 10 - 30 | 0.04 - 0.1 | 0.1 - 0.3 | 2000 - 5000 | 15 - 40 | n/a |

| Extended Aeration | 20 - 40 | 0.04 - 0.1 | 0.1 - 0.3 | 2000 - 5000 | 20 - 30 | 50 - 150 |

| Integrated Bio-Reactor | 10 - 50 | 0.1 - 2.5 | 1.2 - 2.4 | 3000 - 6000 | 5 - 10 | 50 - 150 |

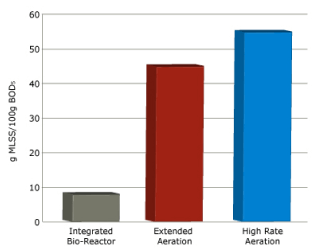

Sludge and Energy Reductions Realized

Significant sludge reduction achieved through use of IBR

- High rate sludge production: 55g BOD5 x 1M x 0.55 = 30.25 Tons/day

- Extended aeration = 24.75 Tons/day

- Integrated Bio-Reactor = 4.95 Tons/day

Sludge reduction per year: (30.25 - 4.95) x 365 = 9,234.5 Tons/year

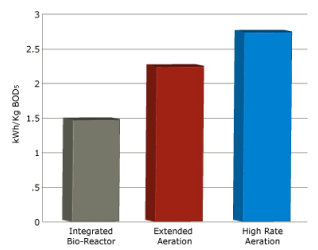

IBR Comparative Energy Consumption

- High rate aerobic = energy required 5,958 kWh

- Extended aeration = 4,182 kWh

- Integrated Bio-Reactor (IBR) = 1,895 kWh

Energy reduction per year: (5,958 - 1,895) x 24 x 365 = 35,591 MW/year.

Client Recommendations

The 2.65MGD IBR system built at Russky Island, Russia has been fully automated and operational since the end of 2012. Our client was so impressed with the project that he left us with his endorsement and testimonial.

View the recommendation letter.During his statement at a preparatory meeting for APEC 2012, former President of Russia, Dmitry Medvedev says that the new wastewater treatment facility alone was worth holding the summit at Russky Island.

Read the statement.