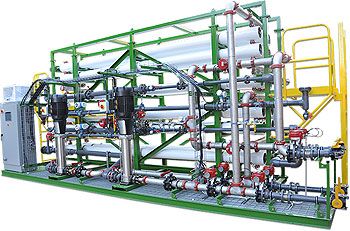

Reverse Osmosis (RO) Membrane System

Reverse osmosis (RO) is the best alternative for high volume/high quality water treatment. The primary purpose of RO is to produce effluent filtrate (clean water) that has very little in the way of impurities associated with salts and other elements besides water. Reverse Osmosis can remove many types of molecules and ions from solutions, including salts. It is used in both industrial processes and the production of potable water from brackish water or sea water.

Chemical analysis of the water is used to determine the proper design of the system, including the pre-treatment system. Various RO testing data are analyzed and considered in order to optimize the membrane's specific applications.

About Reverse Osmosis (RO)

The images displayed on this page are of an RO system that was designed as part of a Zero Liquid Discharge system for an industrial company. Its total design capacity purifies up to 300 GPM of Dissolved Air Flotation (DAF) and Ultrafiltration (UF) pretreated water, containing no suspended solids, oil or grease. Phosphates/surfactants, salts and elements contributing to hardness in the influent water are removed. Each RO membrane system built by Ecologix can also be equipped with 100% redundancy, allowing your plant to continue full treatment even when one line requires cleaning. The entire system can be operated automatically based on an integrated PLC control system.

Key RO System Features

- PLC controlled, touch screen operation

- Redundant system capability

- All required instrumentation including flow sensor, conductivity probe and pressure sensors

- Factory-tested, skid mounted for ease of installation

- VFD for RO feed pumps to maximize efficiency

- Schedule 80 304 SS piping provided for pressures > 150 psi

- Sample valves throughout low pressure piping for ease of operation

- Clean In Place (CIP) Chemical cleaning/filtrate flush system included, chlorine feed system provided for control of biological growth and fouling of membrane surfaces

- Complete O&M manuals

Ecologix RO System Benefits, Applications and Design Criteria

RO System Benefits

- Reduction of TDS values >90%

- TSS reduction to non-detect

- Significant soluble BOD reduction

- 100% membrane redundancy, if required

- Low operator maintenance

- Skidded treatment units for easy installation

RO System Applications

- Drinking / Potable water purification

- Wastewater purification

- Industrial applications

- Aquariums

- Desalination

- Sea water to drinking water

RO System Design Criteria

- Influent Water Pressure: up to 2000 psi

- Influent Water Temperature: 15-35°C

- Power Available: 460V/3Ph/60hz

- Total RO Filtrate Flow Rate: up to 1000 GPM

- Total RO Feed Flow Rate: up to 1500 GPM

- RO System Recovery Rate: 75% or more